By Kelly Combot, Commercial Estimator, Marketing Manager

Winter weather is never kind to asphalt. Extreme cold can lead to contraction and cracking, while constant freezing and thawing can cause buckling and other problems needing repair. Unfortunately, it’s one of asphalts best features that is also its worst enemy once Jack Frost starts nipping at the street.

Here’s how the cold and snow affect asphalt once its laid and during the paving process.

Blame water

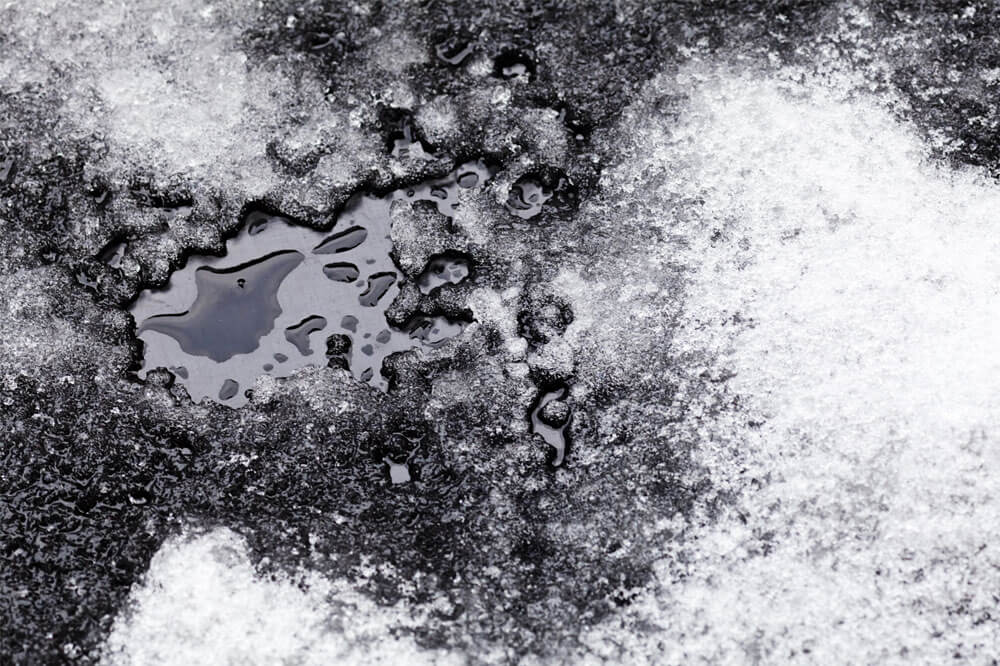

First off, water is the primary reason that paved surfaces (asphalt, concrete, and paving stone) have trouble in the winter. Asphalt is generally made of bitumen (petroleum) mixed with aggregate (a mix of crushed stone, gravel, and sand), and sometimes water. The water in the mixture freezes, expanding as it does so and contracting as it thaws, which can lead to cracking in the pavement.

For asphalt mixes that don’t use water (such as hot mix asphalt or HMA), it’s external moisture that’s the problem. Once pavement has become damaged, moisture will work its way into the cracks and the material beneath will become saturated. When the wet material beneath the pavement freezes, it expands, pushing the pavement surface up and weakening it in the process.

As temperatures rise, the frozen material contracts, leaving a space under the pavement surface. The weakened, unsupported surface will collapse into the space, often as a result of traffic. This creates a pothole that, without proper repair, will expand.

Cold also affects the paving process

Since asphalt is often laid and rolled out in layers and then compacted, road and pathway construction needs to take place during the optimal paving season, i.e. the warmer months of the year. We usually see Winnipeg’s asphalt production plants open in mid-May, and if we’re lucky, they’ll remain open until early November. Paving done too early or too late in the season may be susceptible to easy damage, since the cold weather impedes the compaction process.

Compaction is simply the act of packing down asphalt, which increases its density and makes it harder and more durable. When the cold weather hits, the asphalt mixture cools more quickly, leaving even less time for compaction to take place and making it more difficult for the asphalt to bind together. Paving professionals have to use special tools to estimate compaction time in these cases so that they can lay asphalt in colder weather without affecting its durability down the road (no pun intended).

How Superior combats the cold

We use HMA during our entire paving season, because it’s the best asphalt to use in Winnipeg’s extreme climate. It’s made up of 95% aggregate and 5% asphalt binder (or bitumen). This mixture contains little to no water and is rolled out in layers and compacted.

HMA is the most weather-resistant asphalt mixture available in Winnipeg, and it has the added benefit of chemical resistance, allowing it to hold up against road salt that would otherwise damage a different type of pavement like concrete. During late season paving, HMA has to be heated up a little hotter than usual in order to slow down cooling, which allows for maximum compaction.

Whether it’s permanent paving or temporary seasonal fixes, Superior Asphalt has the expertise and equipment to get your parking lot into tip-top shape. Call or email us today for more information and to book your quote.

Cold weather repairs

If winter is beating up your parking lot or walkway, there are temporary repair measures that can help see you through the rest of the season. One of the most common solutions is a cold asphalt patch. Though temporary, it’s the best fix to get you through the remainder of winter until a more permanent hot mix solution can be used.

If your parking lot is showing some winter wear, contact Superior Asphalt today and we’ll find the best solution to fit your needs.

If your parking lot is filling up with snow, give us a call, since we offer commercial snow removal services as well!